Doing It Yourself (DIY)

6 JAN 2025 - Jeff Willis

DIY (Do It Yourself) Maintenance.

There are two ways to really know your vehicle. One, is taking it to the track. This allows you to really know the physics of your vehicle whether it be a BRZ, FR-S, 86, ort A90 Supra. If you’re able to go to a local track day, you will know the limits of how your vehicle handles, and you will also know the limits of how you are as a driver. The second way to really establish a relationship with your vehicle and the overall platform, is knowing how to wrench on your vehicle. Learning how to work on your own vehicle really provides you with a broader perspective on how labor intensive it can be to do certain things, and most importantly it can help you pinpoint or diagnose things faster when something needs to be addressed. Whether if you need so satisfy your own curiosity, or if you live in a rural area where your local mechanics only specialize in big block Chevy engines, we need to understand with a clearer view of what it takes to keep vehicles on the road.

WHY MECHANICS ARE SO EXPENSIVE AND WHY THEY ARE ALSO WORTH EVERY PENNY

When you walk into a shop whether it be a tire shop or if you’ve been with parents as a younger sibling dropping off the family van to get new brake pads, going to any shop is always an ‘experience’. You have the mechanical potpourri of rubber, oil, brake parts cleaner and other harmful chemicals. And you have the perpetual sound of air ratchets buzzing off, and you have that one 80s rock station that the rest of the mechanics can agree on. Mechanics are always covered in black grime which is fluids that have leaked underneath the vehicle and have accumulated road dirt, and their hands are perpetually scarred and stained. It’s a dirty and risky job, but as they say, somebody has to do it. And no amount of AI can replace a mechanic.

What you don’t know, is that the majority of any established mechanic shop has thousands, if not hundreds of thousands of dollars in tools and equipment to perform repairs in a timely manner whether it be something as simple as changing the oil, or full engine replacements. They have electronic scanner tools to help diagnose and pinpoint problems in modern vehicles, they have lifts to get your car in the air, and they more than likely have highly expensive Snap-On or Mac tools because cheaper tools used on a daily basis break just like any other wear and tear item. Most importantly, skilled mechanics have the patience and tenacity to do things the right way. We will talk about how cutting corners is the worst thing you could do in a few paragraphs, but skilled mechanics must deal with stripped bolts, shoddy previous repairs, and they have to deal with the shock and disappointment of telling most of the general public that their car will need a major repair.

Because of these reasons, this is why established repair shops have a labor rate that will start at $125 an hour on the low side, and upwards of $250 an hour on specialty repairs such as performance mods and restorations. The scary part is that repairs can send many people maxing out credit car cars, clearing savings accounts, or resorting to taking out small loans to get the job done. Why is this all important? Because if you’re reading this blog, chances are that you are driving a performance vehicle that has upgrades done to it. What do mods and upgrades do? It makes us drive the cars harder, which accelerates wear and tear on the engine and drivetrain. Increasing your mechanical intelligence will allow you to help maintain and repair your vehicle, and at the least know what you’d want from an experienced mechanic that needs to do something tedious such as clearances when installing camshafts, etc.

WHERE TO START THEN?

So, you can pay a shop $140 an hour to fix your BRZ, or you can take 2 hours’ worth of labor and invest in basic tools. Now you don’t need the Snap-On, Mac, or other high-end tools especially if you’re not planning on being a mechanic for a living, and you just want to be able to have the ability to install a cat-back or sway bars over the weekend. You can go to your local Home Depot or Harbor Freight Tools or even on your local marketplace to obtain these tools that are must-have’s when working on your car. That being said, these are the tools that you will need to do basic maintenance to your BRZ, FR-S, 86, or A90 Supra. And these tools will generally apply to most makes and models.

Basic Tool Set:

You’ll need a complete socket set that includes a ¼” ratchet, common 3/8” ratchet, and a larger ½” ratchet along with shallow and deep sockets. When working on a BRZ, FR-S, and 86, 99% of the time and of the nuts and bolts will be metric sized rather than standard. Metric sockets are very common on Japanese and foreign vehicles and it’s easier to become familiar with the sizing once you see a bolt and know that it will need the ever-famous 10mm socket. Whereas most American vehicles will be held together with Standard hardware such as ½, 3/8, or 7/16’s nuts and bolts. For those of you wrenching on an A90 Supra, know that it’s 99% BMW and you will need torx-bit sockets and screw drivers with a lot of emotional self-control to work on those.

Flat Head and Phillips Screw Drivers:

One size does not fit all especially with Phillps-head screw drivers. Some heads are sharper or pointier than others, and you will need different lengths to access tighter areas. You are using the wrong head size for a Phillip’s screw; you could strip the + on the head. So just be mindful of that.

Allen Head Wrenches and Sockets:

Several bolt heads in Japanese vehicles and in German vehicles will have Allen Bolt Heads. Many times, when changing brakes, several caliper designs will have long Allen head bolts that hold the caliper together. Also, many times timing belt covers, or engine covers will be secured with Allen head bolts.

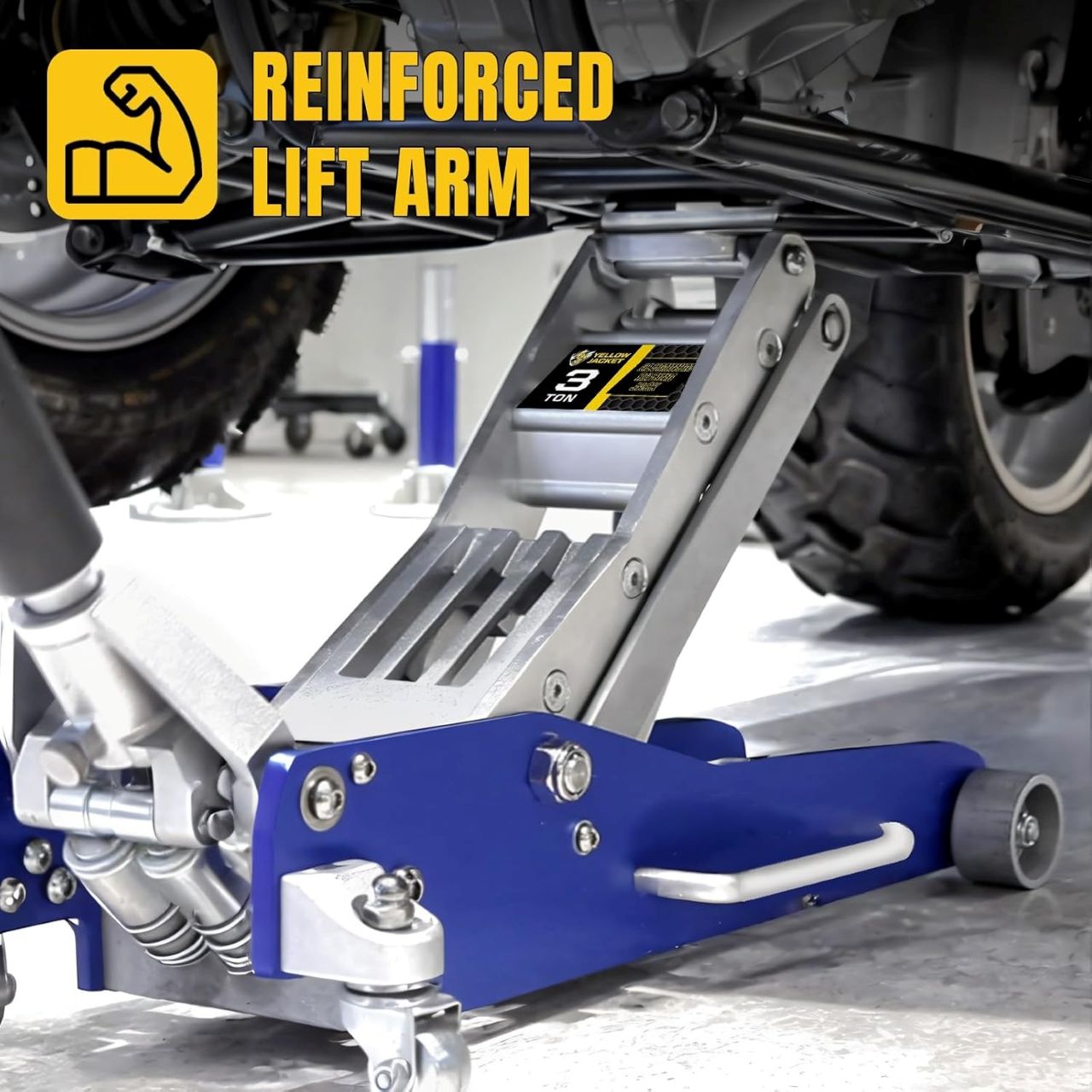

Low-Profile Floor Jack:

Because the BRZ, FR-S, 86, and A90 Supra are naturally low and even lower on coilovers, you will need a low-profile jack to raise your vehicle. MAKE DAMN SURE that you are jacking your vehicle from a proper lifting point under the car. You cannot just slide your jack stand under a car and start jacking up a 3300+lb vehicle from the floorboard otherwise you could push your seat up and misalign the seat rails causing you a whole war of problems in your interior. Look at your owner’s manual, or research on the internet on where you can jack up your vehicle, so you don’t damage the underside. This is one of the most important areas to pay attention to otherwise you could also damage the structural integrity of your chassis. DON’T CUT CORNERS.

Jackstands:

Don’t you ever rely on the strength of a floor jack to work underneath a vehicle. This is how people die a slow and painful death. For the rear, you can jack up your vehicle usually by the rear differential to properly install jackstands on each corner. And on the front lift the car at proper points and secure the jackstands on the frame. Again, make sure you refer to your owner’s manual, or research on where you can place jackstands on your vehicle. When you have your vehicle secured on jackstands, shake the vehicle to double check that it’s safely on the jackstands. MAKE SURE YOU USE A FLAT SURFACE AND DON’T DO THIS ON A HILL MORON. Otherwise, the law of physics will make your vehicle fall off the jackstands and make sure you’re not under the car.

Torque Wrenches:

What rule do most professional mechanics always stand by? That is torquing nuts and bolts to the correct spec. The purpose of torque wrenches is to prevent us from over-tightening something. So, for example when doing something as critical as a timing belt job, the idler pullies cannot be over-tightened because you will wear out the bearings faster. Or on head gaskets, the cylinder head studs need to be tightened in a certain sequence, and they must start with a certain torque spec at first, then tightened again at a higher torque rating to make sure the mating surface is absolutely flat. Or your wheels, if they are not tight enough, your lug nuts will come off while on the road putting your life as well as others around you at risk. Lug nuts need to be 90+ ft/lbs. Now torque wrenches are available in foot-lbs., or inch-lbs. Get both if you can.

Ratchet Wrenches (or wrenches in general):

For areas where you cannot fit a socket. You need to use the general wrench, which is the fork and spoon of your tools in general. Ratchet wrenches are some of the best inventions to mechanics since brake parts cleaner as they save time and are easier on the hands.

Brake Parts Cleaner:

Mechanics will have brake parts cleaner lying around the shop just like your old man did with his cheap beer. When working on an engine or anywhere on the car exposed to oil or fluids, it’s most important to have a clean surface to wrench on. Brake parts cleaner quickly dissolves oil, grease, and basically any other lubricant that has spilled and accumulated caked-on dirt in your engine. Also, it is highly flammable and use it in an open or well-ventilated area otherwise you’ll see purple dragons flying around your head. So be extra careful and do not spray brake parts cleaner on hot exhaust components because lots of fire will happen.

Seems like a lot to have right? It will be some of the best money you’ve ever spent especially when you hone-in on your skills. Plus, over time, your tool collection will grow. Soon you’ll have impact guns and a proper tool chest to store everything. But before you start to do anything, there is something extra important we need to discuss.

DO NOT CUT CORNERS, IN WRENCHING, OR IN LIFE IN GENERAL

Look we all have bouts of lazyisms. Not to target the younger crowd that is merging into adulthood, but with wrenching, there are no cutting corners. Otherwise, you’re going to take a job that should take 20 minutes, and you’re going to turn it into a week-long job, or you will have to get a professional to clean up your mess. There are absolutely no cutting corners when it comes to wrenching on a vehicle. Can’t get to one little bolt because the AC compressor is in the way? Too bad you have to remove the AC compressor. You can’t remove the O2 sensor because your crescent wrench is too long and can’t get the right angle? Too bad remove the exhaust. Want to install gauges in your interior but want to do it clean and correct? Take apart your entire dash and do it the right way. Don’t want to lose the radio stations on your head unit because you don’t want to disconnect the battery while changing the starter or alternator? Fine get shocked and blow relays.

Take your time and do it right. ESPECIALLY, with the nuts and bolts. You’re going to learn real fast what stripping out a bolt means when you try to force something that isn’t screwing on correctly. For many mechanics, trial by fire and many errors are hard lessons that can lead to catastrophe. You can avoid said catastrophes by taking your time and figuring it out so the next time you have to change brake pads, belts, or general wear and tear items, you’ll get more efficient each time. Seems a bit daunting especially when going into unfamiliar territory, but if you want to do this, you need to start somewhere.

SOUNDS INTIMIDATING – DON’T BE A *****

Yeah, it can be. But take your time. Watch the YouTube videos, read the internet, and learn from others when performing a job. Because yes, you might have just dropped $500 on tools, but it is so rewarding when you have spent an afternoon installing coilovers, or a cat-back exhaust with positive results. And you just save yourself a boatload of money by Doing It Yourself.

Stay organized with your tools, make sure all your safety precautions are checked off the list in terms of making sure your car us secured. Spend the $5 and get some cheap safety glasses, and do not cut corners. Once you have performed some repairs or upgrades on your BRZ, FR-S, 86, or A90 Supra, then you will have the mechanical intelligence to know when it’s time to replace something, and you’ll be better at overall diagnosing. Over time, you will have saved yourself thousands of dollars especially if you travel frequently with a daily commuter that needs yearly maintenance to keep the car on the road.