Let's Talk About Clutches

15 APR 2024 - Jeff Willis

LETS TALK ABOUT CLUTCHES FOR YOUR BRZ

We know that the Subaru BRZ, the Toyota 86, and the Scion FR-S are true drivers’ vehicles. It’s been a privilege having an affordable traditional sports car option in a world full of deep 6-figure examples that are flooded with tech, driver assists, traction controls, and lightning-quick PDK style transmissions. For many of us whether we be middle-aged men, or the younger generation who resonates with a direct connection with the car through manually shifting the transmission, the mechanical controllability of throwing this nimble chassis through corners is always an experience, a lesson, and refines you as a driver. These are the reasons why for many enthusiasts who have prominent sportscars in their garage such as a new 911 turbo, the latest and fastest Corvette, or an exotic, many of these enthusiasts will always look at the Mazda Miata as one of the greats because it’s a momentum car. And you really don’t know your car until you’ve had it at the track where you experience the limits of the suspension, the tires, and how to properly setup your apexes.

When the Subaru BRZ debuted in 2013, Subaru surprised the masses as it went against the grain of their traditional recipe of the all-wheel-drive rally-inspired supersedan. However, when the specs started to surface with a naturally aspirated 2.0 boxer engine mated to a 6-speed manual transmission at 2800 lbs., this arrested the attention of many SCCA weekend track day participants.

There are also many of us who had taken a break from modding previous turbocharged models such as the WRX or STI, and although the feeling of boost is a freefall of intoxication, it is also an endless money pit as we need to go faster, and faster. But it can be exhausting to our budgets, our time, and our sanity. Getting into something where you can just get into and drive without worrying about boost levels, the tune, AFR’s under load, weird noises, and all the drama, it’s just refreshing to our sanity.

However, the lack of power and boost does not exempt the BRZ from wear-and-tear items such as brake pads, bushings, and tires. That darned clutch is the reason why we’re able to have all this fun, and what keeps those rear tires spinning.

HOW DOES A CLUTCH WORK?

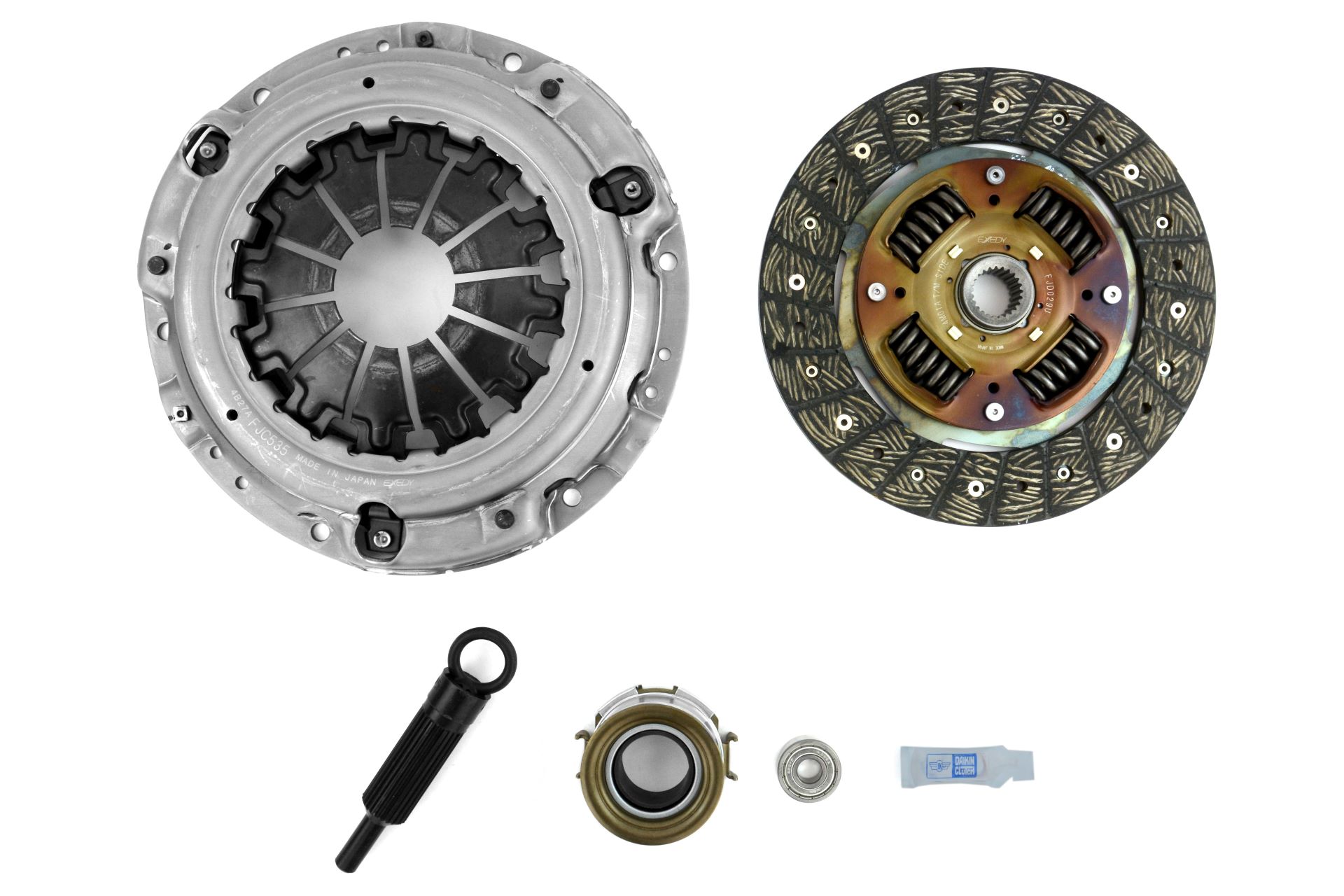

If we look at the clutch kit pictured below, it includes a pressure plate, a clutch disc, a release bearing, a pilot bearing, and a clutch alignment tool for the installation.

Exedy OEM Clutch Kit 13-16 FR-S, 13-20 BRZ, 17-19 86

In an odd way of describing how a clutch works, it almost has parallels with your brakes in terms of having a padded surface that needs to be mated to a flat surface to generate total friction. In the case of your brakes, your brake pads reduce the movement of your rotors by compressing each side of the rotor surface to eventually stop. In a clutch setup, you have the flywheel that is bolted onto your engine’s short block. The flywheel always spins at the speed of the engine as it is bolted onto the back of the crankshaft. All clutch kits when fully assembled will bolt onto your flywheel. Then on your pressure plate you have the other friction surface.

When the clutch is fully bolted onto the flywheel, the clutch disc is sandwiched between the pressure plate, and the flywheel. In relation to brakes, the clutch disc is designed with friction pads to allow the pressure plate to move in unison with the flywheel. So how does the clutch work? When you depress your clutch pedal, you have a hydraulic slave cylinder that has a shaft that pushes a clutch fork that is attached to your release bearing. Typically, there is a sleeve on the input shaft of your transmission, and it is lubricated to allow the release bearing to move back and forth to contact the pressure plate. The job of the pressure plate is to maintain a high level of clamping force on the clutch disc to make sure it is pushed up as much as possible with the flywheel. The pressure plate has what is referred to as “fingers” which the release bearing pushes against when your clutch pedal is pushed in. When the release bearing pushes against the spring-loaded fingers on the pressure plate, the pressure plate will slightly release tension on the clutch disc, allowing the disc to float without spinning with the flywheel. When the clutch disc is free from the friction between the pressure plate and flywheel, this allows you to change gears.

SO, WHAT IS A SLIPPING CLUTCH? WHAT IS A WORN-OUT CLUTCH?

When you wear out your brake pads, you will hear a metal-to-metal noise because the pad material is gone. The same method applies to a clutch disc. Your clutch disc has friction pads on each side of the disc. The pads need to make a high level of friction contact with the flywheel on one side, and to the pressure plate on the other side. When you wear out your clutch disc, this means that the pad material has worn down enough to not be able to hold a tight grip with the flywheel and pressure plate. When you get on the throttle and your car revs high, but you’re not going faster, this is because the clutch disc cannot move with the speed of the flywheel and pressure plate. When you completely lose friction, your car will not move, and you won’t be able to get into gear. Now when slippage is used in terms of “slipping the clutch” This means that you can release the pedal gradually as you would when daily driving the vehicle, rather than dumping the clutch pedal when launching at a drag strip. When the clutch is slipping when you’re not using the clutch pedal, that means you need a new clutch.

WHEN DO I NEED TO UPGRADE MY CLUTCH?

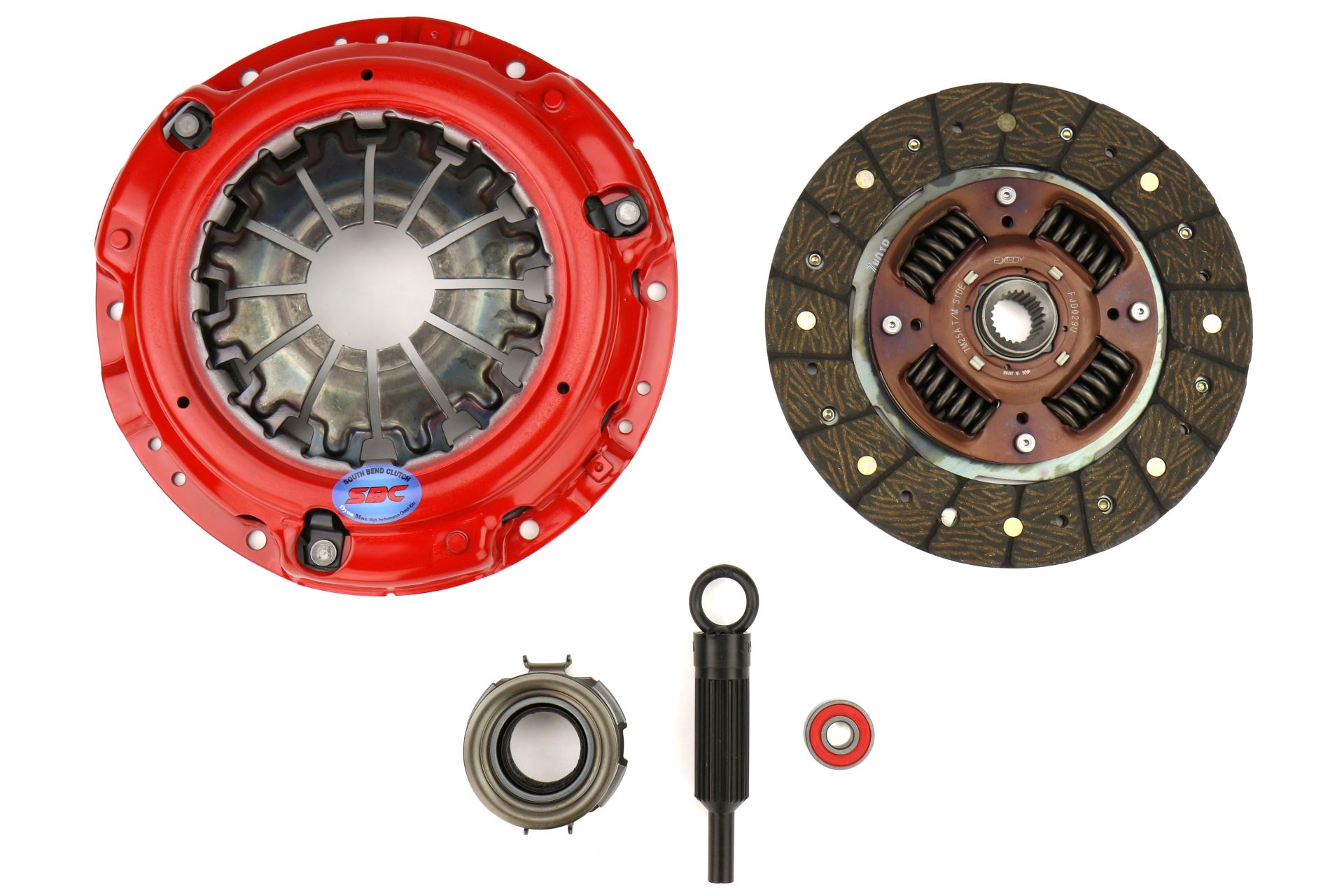

This is dependent on your current and future mods, and your driving style. An upgraded clutch will have a higher torque rating. So, if you have a stage 2 disc, you will typically get a pressure plate that has a higher clamping load, and your clutch disc will be made with pads that can endure more heat. There are several different aftermarket options to look at. Now with the Subaru BRZ, Toyota 86, and Scion FR-S, performance mods are limited when compared to a WRX. Many owners from a performance spectrum will do an intake and exhaust because it’s a naturally aspirated engine. A stage 2 clutch will typically have the torque rating needed to handle these mods, and if you’re relatively stock but enjoy track days and autocross events, a stage 2 will also maintain a high level of performance especially when your engine is living in the upper-RPM range. Now for those of you who added forced induction, and have built your motor to withstand boost, with tuning pushing 350 WHP and above, you will obviously need a clutch strong enough to hold that power.

South Bend Stage 2 Daily 13-21 BRZ, FR-S, 86 (rated to 315ft-lbs.)

WHAT IS A SPRUNG VS UNSPRUNG DISC?

When researching clutches and when shopping for clutch kits, you will see sprung vs unsprung in the title. When looking at clutch discs, you will generally see 4-6 springs integrated into the clutch disc. These springs are designed to absorb shock on the disc when releasing the clutch pedal, and they help with slippage and feedback. The only time you will see an unsprung clutch disc is if you are buying a clutch kit that has an extreme torque rating. Now you will find unsprung discs in a multi-plate clutch kit which we will discuss in a second. But in some extreme cases, you will find unsprung examples in single-disc clutch kits with a massive torque rating. These are for track use only and will drive terribly on the street and almost impossible in bumper-to-bumper traffic. And this is because you can’t slip these clutches, and it’s like an on and off switch. You would almost chirp the tires every time you release the clutch, and you really have to get used to how you would drive your vehicle and makes life difficult when trying to go to work in the morning. If you need a clutch with a high torque rating, get a multi-plate clutch, or find a disc that has 6 springs, or 4 large springs so that you have slippage and feedback at the pedal, and can drive the car on the street.

HOW DO MULTI-PLATE CLUTCHES WORK?

XClutch 8” Twin Rigid Ceramic Clutch Kit 13-24 BRZ/FR-S/86

Now single disc clutch kits that have a profoundly large torque rating will have a stiff pressure plate to smash down that clutch disc against the flywheel, the clutch disc in many cases, will be unsprung, and it will have much larger friction pads to maintain a tighter hold. However, the clutch pedal will be very heavy, and at many times, there is no slippage when going from a dead stop. Very uncomfortable on the street, but appropriate at the drag strip. The solution for vehicles making substantial amounts of horsepower, are multi-plate clutches. Multi-plate clutches feature a steel basket that includes 2-4 discs (2 are the most common), and the discs are separated by floater plates. Now multi-plate clutch kits are superior in racing due to the overall clamping force.

Multi-plate clutch kits are generally louder, and it is normal to hear chattering due to the floating plate that rattles between your discs. Now with older multi-plate designs, the discs would disengage very quickly so you really had to manage initial roll off the line otherwise you’d kill the car at a redlight. Newer design multi-plate clutches have larger carbon discs that help with drivability, but really it also depends on your release bearing setup. Multi-plate clutches will include their own release bearing, but there are manufactures such as the highly esteemed Tilton, who make release bearings that make multi-plate clutch kits very streetable if you’re making substantial amounts of power but want to enjoy the car on the weekends at local car meets and such.

Multi-plate clutches will also include their own flywheel to accommodate both sizes, and mainly the balance. These flywheels will be much lighter when compared to OEM, with that being said, the engine will rev faster due to the reduction in rotational mass. This result also increases both horsepower and torque.

DO YOU NEED A LIGHTWEIGHT FLYWHEEL?

Exedy OEM Style Flywheel 13-16 FR-S, 13-20 BRZ, 17-19 86

Actually, for a naturally aspirated platform, there are only a few mods that can increase the power and throttle response outside of an intake and cat-back exhaust. One of those mods is a lightweight flywheel. Lightweight racing flywheels are made with chromoly steel, or other lighter materials to reduce the rotational mass of the crankshaft as mentioned with multi-plate clutches. It’s the same reason why lightweight crank pullies, and other lightweight pullies in the engine increase the performance, because your engine has less resistance to move. The less resistance you have, the more horsepower and torque will be gained. In other Subaru models, sometimes a lighter flywheel can trigger a check engine light because the ECU cannot recognize the power gains outside of it’s programmed parameters so there is a risk. For the most part you should be safe, or have it tuned to maximize the power potential. The only drawback is that it effects drivability slightly, but this completely depends on what clutch you have installed.

Now there are some drawbacks of a lightweight flywheel. It takes a little more attention to drive because your engine revs faster when compared to an OEM flywheel, and it makes the clutch harder to slip when driving from a stop. It’s something that you will have to get use to, but it gets a little harder if you choose an aggressive clutch designed to hold over 300 lb. feet of torque. Your OEM flywheel will suffice with all single disc clutch upgrades, but for those of you who want to squeeze out a little extra horsepower, the lightweight flywheel can be a good upgrade when replacing your clutch.

DO A PROPER CLUTCH BREAK-IN

Some clutches require a 300-mile break-in to establish proper friction contact between the disc, and the flywheel on one side, and the pressure plate on the other side. Break-in miles are when you are easy on the clutch and are not revving out the motor. You need to get some proper heat cycles embedded in those friction pads, and most of those miles must be in regular traffic, and not all on the highway. Now this really pertains to high-performance clutches, and clutches designed to hold more power and torque. If you’re replacing your clutch with an OEM clutch, then you should be okay as long as you’re not dumping your clutch pedal from redlight to redlight. Performance clutches that hold more power need that break-in period because the disc material can differ whether it be ceramic, metallic, or carbon. What happens if you don’t perform a proper clutch break in, and just start driving the car hard? This pad material can stamp itself on the flywheel and pressure plate, which can lead to an uneven mating surface, increasing the overall wear, or you could glaze the flywheel or pressure plate, coating the surface with disc material which would decrease friction, causing your clutch to slip.

DON’T DESTROY YOUR CLUTCH

How does launching eventually cook your clutch? If you’re at a drag strip or launching your BRZ off the line at your local autocross event, more than likely some of you will release or dump your clutch to get off the line faster. It’s just a necessity to remain competitive. However, it is very hard on your clutch, thus, there are aftermarket clutch options that can handle these situations for a longer period. When doing a launch, you rev your motor into the upper RPM range, some bouncing off the rev limiter, and at this point the flywheel and pressure plate are spinning very fast, near peak speeds, then when you dump the clutch, the pressure plate literally slams the clutch disc onto the flywheel, where the clutch disc has a split second to absorb all of the engine and drivetrain’s power and torque, and transfer that energy to the tires.

How does launching wear down your clutch? When you dump your clutch or release the clutch in the upper-RPM range, and as mentioned, the disc goes from a floating state when the clutch pedal is depressed to suddenly instantaneously having to match the speed of the flywheel. Material of the disc gets shaved off and left on both the flywheel and on the pressure plate. Almost like how your tire will leave marks on the pavement when dumping your clutch. Because the disc is responsible for transferring the power and energy from the engine to the transmission, and to the wheels, it also absorbs a lot of heat.

This is why you need to get a clutch that matches your power levels. Granted the BRZ, FR-S, and 86 are naturally aspirated and aren’t known for making a large amount of horsepower, many owners and enthusiasts track and race these cars. You need to have the right clutch that can absorb the launches, the fast shifts, and especially, you need the right clutch that can handle long periods in the upper RPM range. We get it burnouts are fun, drifting is fun especially because you must dump the clutch several times to modulate slides, and racing is fun. But overly abusing your clutch will result in a much shorter clutch life.

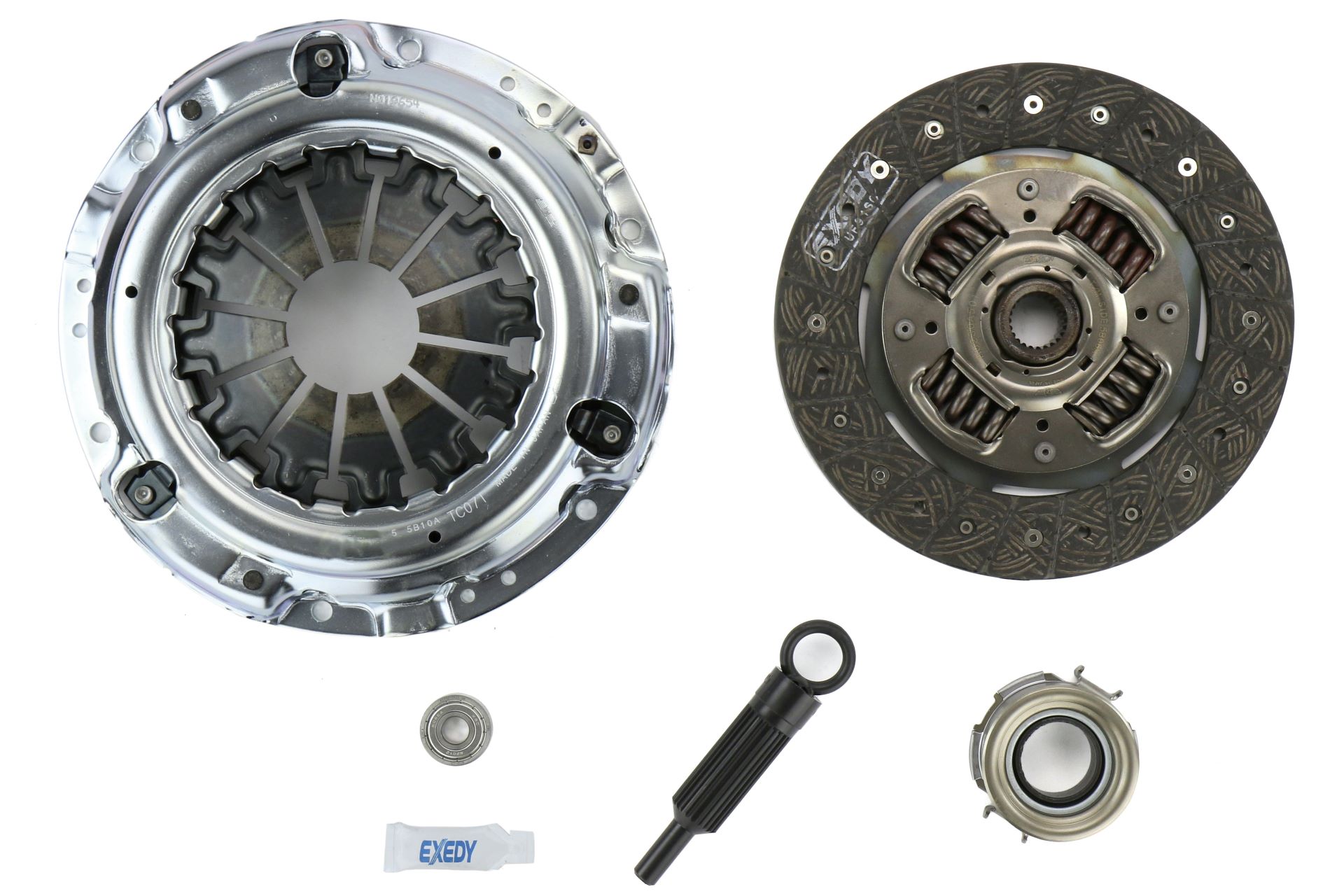

BE SENSIBLE WITH YOUR CLUTCH CHOICE

Think about what mods you will do inn the near future that increase the power and torque of your BRZ/FR-S/86 and think about how you will use your vehicle. Do you go to weekend autocrosses, are you going to add a turbo kit? Or are you going to keep your car relatively stock? Because the wrong clutch can really affect the drivability of your BRZ. Getting a clutch that is overly aggressive for your driving purposes will really hurt your daily driving experience. Meaning, if you drive your BRZ every day and just have a cat-back exhaust as an upgrade, don’t get an unsprung clutch kit rated to 600 HP thinking that you’ll be fine. Now it may be fine at the track, but very hard to drive in stop and go traffic. If you like to participate in the occasional weekend track event while having an OEM-like feel, choose a good stage 1 or stage 2 clutch that’s a nice upgrade over OEM, but can enjoy every day.

Exedy Stage 1 Clutch Kit 13-21 BRZ/FR-S/86

UPGRADE THAT CLUTCH FORK WHILE YOU’RE AT IT

Verus Engineering Billet Clutch Fork 13-24 BRZ/FR-S/86

Lastly, when you are changing your clutch, it is a good idea to replace the clutch fork. The OEM clutch fork is known to have broke while in action, which will leave you stranded on the road. Verus’s example features strong billet construction and will include a new pivot ball to ensure an overall better clutch and pedal operation.