YOU’VE BLOWN YOUR ENGINE: What do you do now?

9 JUL 2025 - Jeff Willis

As car enthusiasts, most, if not all of us will at some point in our lifetimes experience an engine failure. The immediate thought when it happens is, gosh this is going to be expensive. Yes, it will be. Engine failure happens, and it will happen to the best of us. How does engine failure occur? It happens for several reasons. Lack of maintenance, low on fluids, bad tune, or driving your car hard without giving it a chance to cool down. And it happens especially to us car enthusiasts who drive fast cars and like to compete in them.

Engines also fail simply due to high mileage as well. Every moving part in your engine is a wear-and-tear item. Obviously other parts will be worn faster such as a clutch, alternator, etc. But when losing an engine, it means that something in the main internal guts has failed. 9/10 times it will be a rod bearing or a main bearing that has let go sending a rod through a block (learning the hard way) or by causing rod knock (a Subaru prevalent boogie man).

SUBARUS AND ROD KNOCK. WHAT IS THE DEAL

This knocking noise is called rod knock for those of you who are very new to cars or have just been deprived of the internet. What is rod knock? Look at these connecting rods right here:

BC I-Beam Extreme Connecting Rods 2013-2021 BRZ/FR-S/86

Looking at this set of connecting rods, you will notice that there is a small hole on one end. This is where the connecting rod is connected to your piston using a wrist pin. The other end connects to your crankshaft. The two bolts on the end of each connecting rod attach to the rod cap. The larger circle is where your rod bearings are installed, and sandwich between your connecting rod, and your crankshaft journal. The bearings on your crankshaft are the most critical components inside your engine and are responsible for allowing the rotation assembly to make countless revolutions as your motor turns without friction.

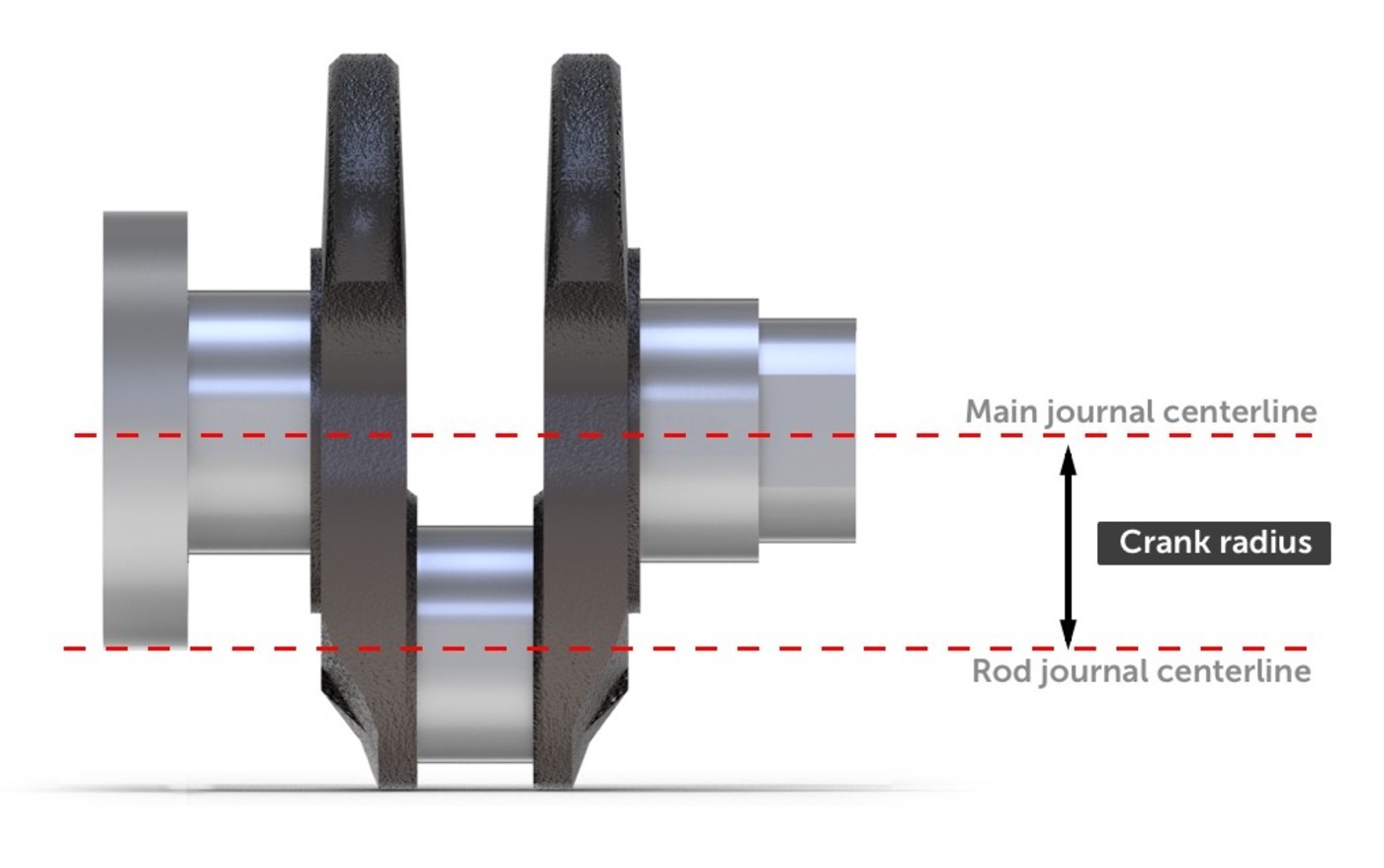

What makes bearings the most crucial components inside your engine? This is because they are installed with carefully measured tolerances by the factory, or by your machine shop depending on how bad your journals were scratched after the machining process and with new bearings issued. And when the term, journals are referenced throughout this article, here is a picture of a crankshaft with main and rod bearing journals in the image:

And this is a bearing. Whether they are crankshaft main bearings, or rod bearings, they will look the same in terms of shape. The crankshaft main bearings will always be bigger:

ACL STD Race Rod Bearings 2013-2021 BRZ/FR-S/86

Now in this photo of these ACL rod bearings, you will see 8 halves. Two will come together. One end will sit inside the connecting rod upper half, and the other bearing will install on the connecting rod cap. For crankshaft main bearings, one side of the bearing will sit inside the short block girdle (for lack of better term), and the other half of the bearing will sit inside the main bearing cap.

The reason why these are so crucial, is because they are measured in both clearances (usually around 0.025” but will vary depending on machining), and in torque specs. In that measurement of 0.025” as an example, the bearing will allow a small film of oil to sit between the bearing, and the journal of your crankshaft whether if they are rod or main bearings.

This film of oil between the bearings and the journals of the crankshaft will be responsible for the oil pressure that your motor produces. At any time if those clearances are compromised, you will lose oil pressure. This means that if you do lose oil pressure and you see 0 on your factory or aftermarket gauge display, your bearings are most likely cooked.

How do bearings go bad? When you’ve heard someone say they “spun a bearing” what does that mean? That means that the bearing welded itself onto the crankshaft journal due to the bearing clearance getting so wide it allows metal-to-metal contact. You can also lose an engine bearing due to lack of lubrication, a bad tune, 2-stepping or anti-lagging on turbo cars because every time you 2-step there is an explosion in the cylinders that makes the rod slam the bearings. Heat from running lean and detonation will also kill or your oil’s viscosity and lubricating properties to fully protect your bearings as well.

With Subaru’s and the boogeyman of rod knock and why is it common? And the issue can be because of the flat-four engine design. When you have a horizontally opposed engine with contributing factors such as a weak OEM oil pickup tube, and lack of proper baffling, this is why Subarus lose engines (at least when they do). Which brings us to the next disclaimer.

MOST FAILED ENGINES ARE FROM RACING, LACK OF MAINTENANCE, OR BEING A DUMMY

It doesn’t matter what BRZ, FR-S, 86, or what Subaru you drive. If you’re a responsible owner and perform your oil changes, make sure your fluids are topped off. Use premium fuel and stay on top of maintenance, your vehicle is going to last a long time. Motors that fail on these platforms happen from racing, high-performance driving conditions, wrong oil weight, lack of maintenance, and being a dummy by money-shifting, doing donuts, or any activities where the engine is at redline and the oil is sloshed to one bank of cylinders.

All Subarus will naturally consume some oil. But if you’re not on top of it and you let your oil levels get to the bottom of the dipstick and you decide to do some parking lot donuts the first time it snows, the oil that is in your engine will shift to the other side, starving the other bank of oil.

After all of that reading. ROD KNOCK is where the bearings in one or more of your connecting rods had worn themselves down enough to where the rod will have enough clearance to bounce on the rod journal. The knocking noise is the connecting rod smacking the rod journal on the crankshaft.

WHAT IF YOU BLEW YOUR ENGINE? THEN WAT?

The absolute dumbest thing you can do if you think you hurt your engine is to start your car and continue revving it lol. This is only going to make the damage worse because what if you do have rod knock? You are only digging the damaged bearings into the metal deeper which can cause enough damage to the journals where there is no return.

Blowing an engine is very hard. Both financially, and if your BRZ, FR-S, or 86 is your only means of transportation. Then your car will be down for a month at least depending on your budget and the availability of a competent mechanic.

What is devastating about losing an engine bearing, is that it sends metal shavings throughout every possible crevice, nook, cranny, and catacomb of your engine. After the motor has been disassembled, the short block needs to be hot tanked, and thoroughly cleaned to make sure every single oil and coolant passage is free of metal. Otherwise, that metal will go through the motor if rebuilt through uncaring eyes. Anywhere where oil travels, shavings will follow and can make it pass your oil filtering system. This means that the heads will also need to be checked and cleaned as well.

And at this point you need to get a new water pump as well as an oil pump, while also making sure your oil pan is also thoroughly clean and free of debris.

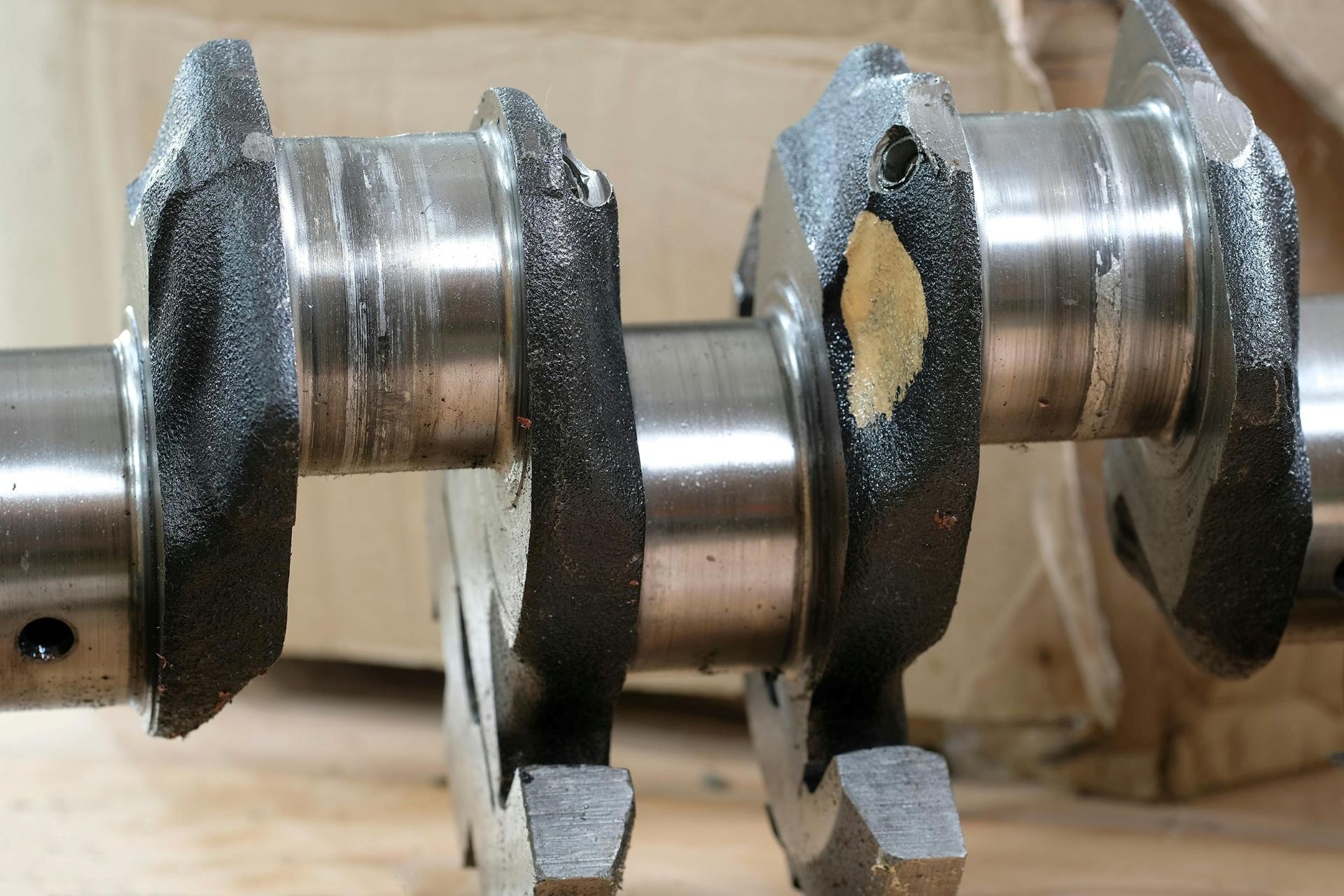

What is time consuming is the machining. To make sure your engine is rebuilt properly the journals must be repaired:

The journals need to be grinded down and smoothed out again. This is where a machine shop will issue larger, thicker bearings to compensate for the lack of material that was removed in the machining process. And if the damage is too great, they will weld new material onto the journal, then re-grind and polish until a suitable bearing can be used again.

All of this labor-intensive process is the result of having both a mechanic to remove and tear down your motor, then the machine shop needs to repair the journals on your crankshaft. More than likely increase the bore on your cylinders due to piston slap. Possibly line-hone your main caps. Then issue you the correct bearing size, along with pistons that have the correct bore and ring size to work with your newly re-machined and bored cylinder walls. This is where rebuilding an engine can become time consuming. Everything then must be assembled with all-new seals and gaskets. You cannot re-use any gaskets unless they are exhaust gaskets.

OPTION 2 - GET A NEW ENGINE THAT IS ASSEMBLED

Now when one loses an engine, your brain gets scrambled especially if this is your first time, and you don’t know what you’re doing. You don’t know whom to talk to. You go on FB and ask local Subaru groups who is the best local mechanic, and you will get 50 responses before it turns into the a-typical argument of who screwed whom over, and you really have to do your research and make sure you only pay a mechanic when the job is complete. There are several instances where mechanics want people to pay half up front if not more, and just let your car sit on their lot for months on end without any work being performed. So, make sure you do your due diligence before you invest any of your hard-earned money because this will be expensive no matter if you have your original motor rebuilt, or if you decide to go with option 2, which is purchasing an assembled short block.

Now from the dealer, a brand-new OEM short block assembled with a crankshaft, rods, pistons, all with factory clearances will be around $2800 plus tax.

In this case, your mechanic would assemble with motor with new head gaskets, freshly cleaned/machined heads, new head studs, and with all accessories installed such as your oil and water pump, camshafts, timing belt and sprockets that are timed properly. AC condenser, all pulleys with serpentine belt, all sensors, all of your fuel system components minus the fuel line leading to the tank, as well as your engine wiring harness. When all of these things are installed, the motor is ready to be dropped back in.

Now if you have your engine rebuilt with new pistons, rods, re-machined crankshaft and new bearings installed it will also go through the same process. The only benefit from buying a new OEM Subaru short block as opposed to having your engine built, is that you have the option of upgrading to a forged piston and rod setup. You just have to make sure that the mechanic knows what they’re doing and that they use the right machine shop in the assembly process.

There is a saying that the cheapest Porsche you buy will be the most expensive Porsche you buy. That analogy rings true with engine builds. Do it right the first time or you will be paying for it twice. Building an engine is just more time-consuming with the removal of the engine, the disassembly to investigate why it failed, and if the crankshaft is salvageable. Then sending everything to a machine shop.

Buying an assembled block means that the mechanic will send your heads off to the machine shop to make sure it is cleaned. Install new valve seals, keepers, guides, and make sure your valve springs are properly sealing. Once the heads are cleaned it is all re-assembly onto the new block, and it can save you a few weeks of time.

OPTION 3 – YOU GO FULL-ON BROTHER AND GET A BUILT SHORT BLOCK

Option 3 will cross your path especially if you’re an enthusiast, and want the comfort of knowing that you’ve got forged internals even if you keep your car stock and only make 200 HP. You are going to spend double or more on a built short block when compared to Subaru OEM, but these short block options are made to handle forced induction such as a supercharger or a turbo kit if you decide to go down that rabbit hole in the future.

The built short blocks that we carry are from IAG Performance, which are one of the most established aftermarket performance shops and suppliers in the Subaru performance industry. We carry a few FA20 options that have been blueprinted and assembled to handle boost.

This example is a great entry-level short block for $4799.00. This unit has IAG’s forged H-beam connecting rods and ARP 2000 rod bolts. It also has JE forged pistons, and it is assembled using King or ACL bearings. This block is rated at 600 HP, and the compression is slightly lowered to 10.5:1 to handle boost when compared to the OEM compression ratio which is naturally high for that low-end torque at 12.5:1.

IAG 600 FA20 Subaru Short Block 10.5:1 Compression Ratio 2013-2021 BRZ/FR-S/86

But then, IAG offers their IAG 800 BHP block that maintains a factory compression ratio, that way you have that low-end torque with forced induction. At $6299.00, this is the best built short block for those of you who want OEM-like drivability, but it is built to handle up to 800 HP at the crank if you decide to add a supercharger or a turbocharger setup later.

IAG 800 BHP FA20 Short Block 12.5:1 Compression Ratio 2013-2021 BRZ/FR-S/86

BUT REMEMBER

We know that you just spent an entire fortune whether you just spent the money investing into an IAG short block, or if you paid a mechanic to rebuild your existing motor. This is an investment that is never easy to handle, and we certainly don’t want to blow another engine again anytime soon unless you have deep pockets. But for the common working man, blowing an engine certainly teaches us many things. Especially not neglecting your new engine.

Do your break-in correctly. This means keeping the RPM’s below 3kish RPM and let your piston rings settle, and make sure that they are sealing correctly. Make sure that your mechanic changes the oil immediately after the initial startup to remove any natural metallic elements that will happen once you fire your motor up got the first time. In fact, you’re going to be changing the oil at least 3 times in the maiden voyage stage. Once right after startup. Once more after a few miles around the block. And another time right after break-in miles which is usually 500-1000 miles. The longer, the better. And break-in miles is another argument from online experts. After break-in, make sure you stay on top of those oil changes at the right intervals using fully synthetic formula, and at the right weight and viscosity.

Once of the common failure points in Subaru engines is the factory pickup tube. When it fails, you lose an engine because the OEM pickup tube can crack at the welds which will make the tube suck in air rather than oil. When you have air instead of oil, that oil cannot lubricate those bearings.

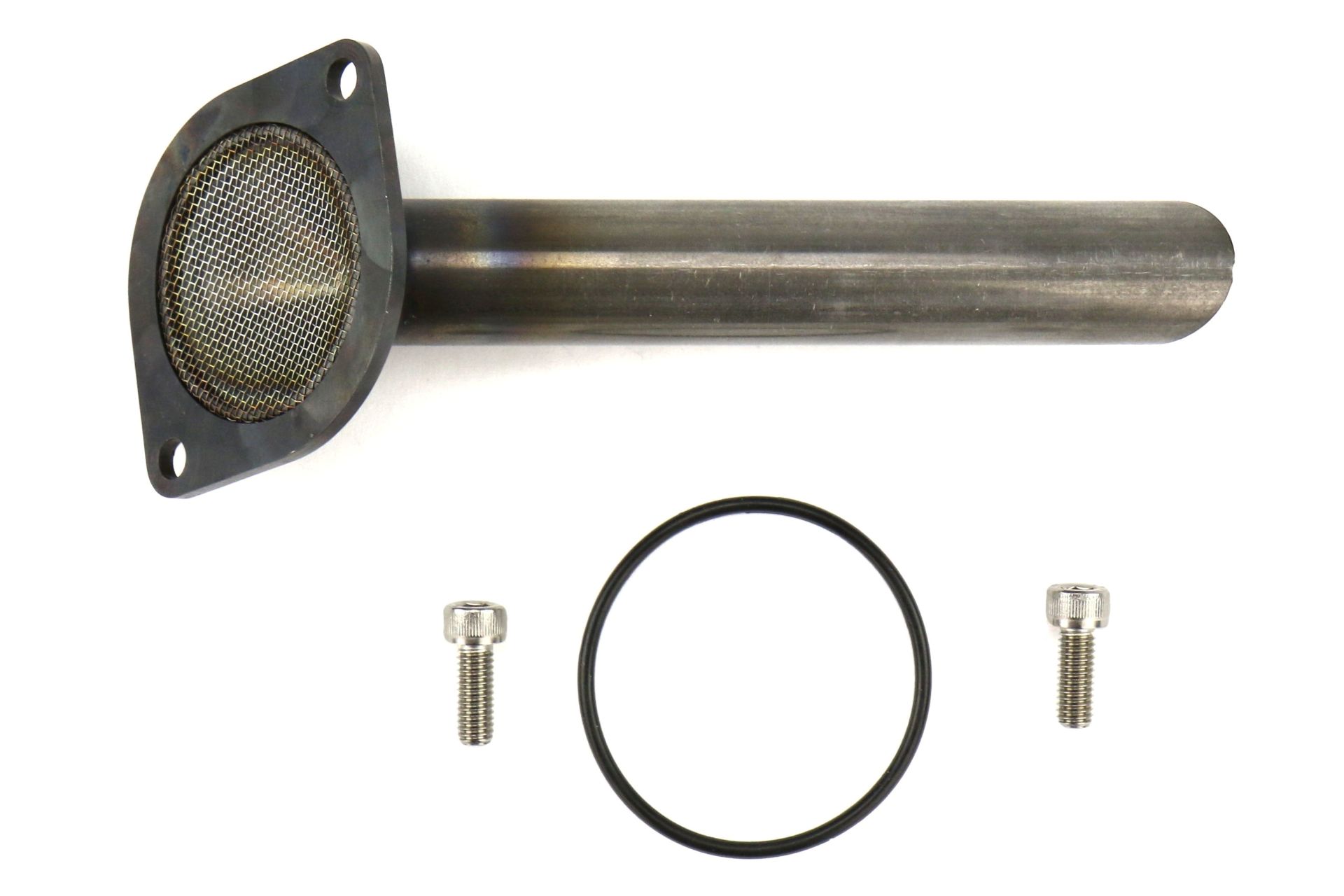

This Killer B pickup tube will be the answer:

Killer B Motorsports Ultimate Oil Pickup 2013-2021 BRZ/FR-S/86

IT’S EXPENSIVE, DO WHAT BEST SUITS YOUR BUDGET

Again, do it right once or pay for it twice. We know that many of you here are capable of doing your own work. But for those of you who simply don’t have the tools or the time, make damned sure that you are choosing the right shop and the right mechanic. Make sure they are known and trusted, and NEVER pay the guy who will do it cheaper. It is one thing paying a guy cheap to replace a starter or alternator, but when assembling a motor, the environment has to be 100% clean and dust-free. And they need the right tooling to make sure the clearances are 100% spot-on. Get the most out of your budget so that you can continue enjoying your car and keep it on the road.

CLICK HERE FOR ALL SHORT BLOCKS

CLICK HERE FOR ALL MOTOR BUILD COMPONENTS